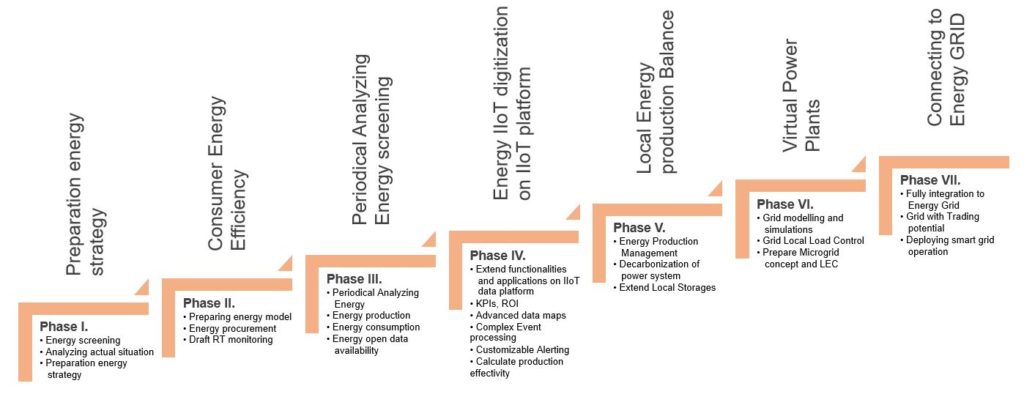

Energy from monitoring to management (7 steps)

Goal - short description

Set up and launch the company’s energy concept so that decision-making on processes and investments is also included from the point of view of energy costs, thereby streamlining and optimizing energy inputs for the production of a unit of product.

Description

With rising energy prices, their monitoring is more than necessary. Energy is hidden in every part of the company, and energy as a whole constitutes a non-negligible part of the company’s costs. Ignorance of the structure of the breakdown of costs for individual parts of the company, starting from the production technology itself, through air conditioning, warehouses and administrative parts, can lead to ineffective or insufficient cost-saving measures. By knowing the consumption structure of individual types of energy down to their source media, it is very easy to calculate and plan investments in production or storage, e.g. electric energy (EE).

Solution

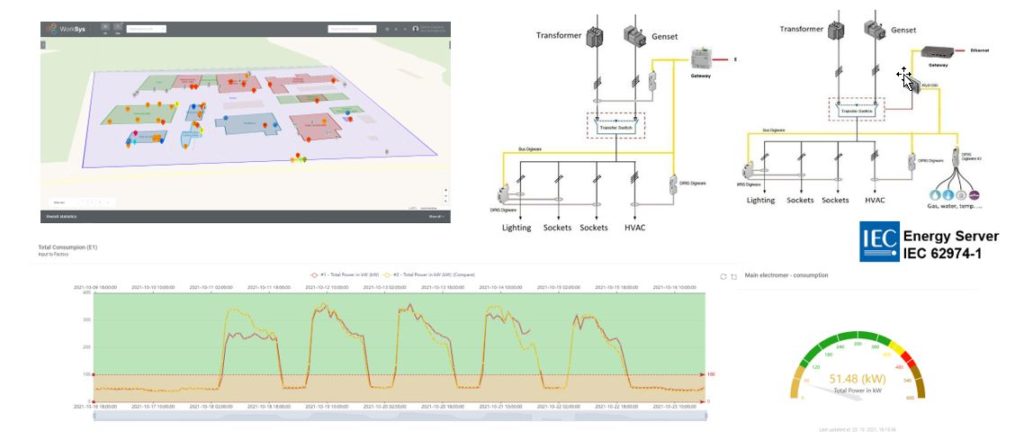

By setting a strategy of measurements at the entry points of individual energy media and subsequent secondary measurements, objects that have a fundamental or significant influence on the total consumption of the medium were quickly identified, e.g. EE. By combining secondary measurements and importing data from the distribution company, the customer knew how and how close he got to the reserved capacity (RK and MRK). In the first step, he very easily avoided energy peaks and trivial inefficiencies (machine not switched off, lighting, etc.) with light process measures, and subsequently, by observing consumption from secondary measurements, he learned in detail the behavior and optimal performance vs. consumption of their technology. By combining it with information about the manufactured pieces, he made calculations a reality and set alerts for potential inefficiencies. It also turned out that, for example by measuring EE consumption on compressors or other motor parts, their condition is effectively monitored, which generates additional and significant savings in the maintenance process as well.

What makes the solution unique

By applying the methodology in the energy sector and online measurement, we are able to identify potential inefficiencies “remotely” and to realize the consumption according to the operating technology and the size of the company.

Benefits

- Setting up the energy concept for the company regardless of the number of collection points

- Checking the state of contractual parameters for individual collection points in relation to 15 min. consumption curve for individual collection points

- Preparation of the proposal of main and secondary measurements for sufficient monitoring of all parts participating in the consumption of individual energies

- Energy management with maintenance of the process loop (Monitoring, Evaluation, Planning, Implementation of measures) to maintain already achieved results

- Preparation of proposal for setting reactive scenarios towards production or operational technologies

- Preparation of proposal for planning energy production and energy storage with the aim of internal regulation of production and consumption

- Towards a smart energy grid

Return on Investment (ROI)

Investment

16.310 €

Savings

21.700 € / year

(12% of EE costs)