Monitoring the amount solid particles in the production process

Goal - short description

Monitoring the impact of dustiness (according to the size of individual solid dust particles) on production quality, condition and maintenance of production equipment.

Description

In the past, the customer purchased and currently uses a machine for approx. 3M EUR, which is used for the production of semi-finished products. During its operation, there is an increased production of solid dust particles, which the customer wanted to monitor.

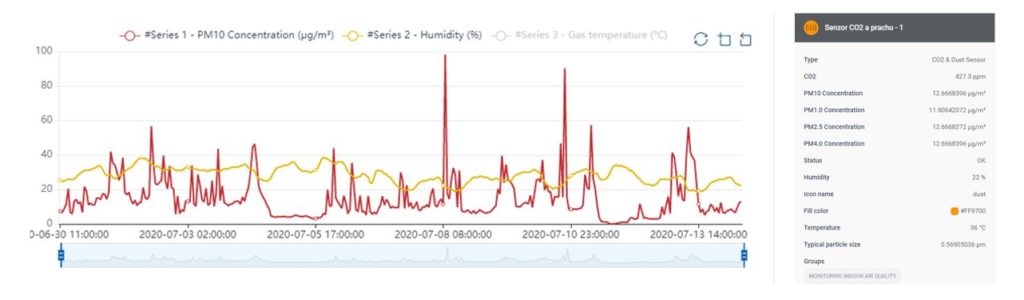

Based on the customer’s request, combined temperature, humidity, CO2 and dust sensors (IoT Sensor Box Enviro) were installed in the production hall.

Solution

According to the data, it was found that during the performance of the machine, there was a significant increase in dust around the machine periodically after a certain period of time, which was clearly visible on the graph. As expected, this is caused by the pollution of the filter and its failure, when it had to be replaced. Based on the measurements, a new filter change process was set up by the customer, which extended the life of the filters and also extended the machine’s uptime by reducing downtime.

What makes the solution unique

We give customers the opportunity to look at their factory through data that can often be obtained in a simple way and with an affordable solution. In this way, the customer can make decisions based on real data and find a hidden savings potential that he did not even know about until now.

Benefits

- Operational monitoring of the state of production equipment based on environmental values of dust particles, e.g. filling of filters or other filtering technologies.

- An effectively set filter unit replacement cycle based on their filling (wear) without the risk of jeopardizing the machine or the quality of the final product.

- Clearly demonstrable environmental values of the production environment during the entire production period and thereby guaranteed traceability of production quality.

Return on Investment (ROI)

Investment

5.360 €

Savings

288.000 € / year