Monitoring of temperature, humidity, CO2 and amount of solid parts

Goal - short description

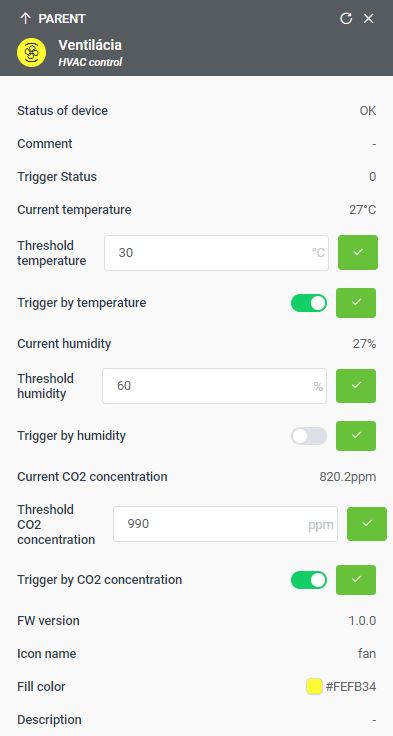

Setting up regulated air exchange in the hall based on CO2 measurements, as a tool for energy efficiency and air quality for workers. The goal is to manage the exchange of air and the energy “stored” in it (heat, cold), only if the set values of CO2, temperature, humidity, or their combination are reached.

This will maintain the working comfort of the employees and not waste energy through unnecessary regular ventilation, even if there is no real reason for the need for air exchange in the production premises.

Description

The customer wanted to monitor, visualize and subsequently control the level of CO2 and other quantities in the production hall with an area of approximately 6000m2, where he regularly ensures air exchange according to recommendations. In this hall there are approximately 50 pieces of smaller injection molding machines, 7 semi-automated assembly lines and a number of production, management and service workers. It is also necessary to replace the control unit to control the air conditioning.

Based on the customer’s request, combined temperature, humidity, CO2 and dust sensors (IoT Sensor Box Enviro) were installed in the production hall.

Solution

According to the data, it was found that the individual measured quantities change significantly depending on the production load, the number of people at individual workplaces and the external conditions. Based on the measurements, the customer set a new air exchange process, which extended the time between individual exchanges. Based on the measurements, the customer set a new air exchange process, which extended the time between individual exchanges. The system automatically alerts service workers about the need for air exchange by sending a notification.

What makes the solution unique

The customer has the opportunity to find the ideal air exchange model based on real time measurements and set automatic scenarios according to standards and expectations without the need to upgrade the control unit.

Benefits

- Energy efficiency – reduces the number of air changes and thus significantly saves the costs invested in heating, cooling and the actual operation of air conditioning.

- Permanent monitoring of the internal working environment with demonstrable environmental values on the timeline (OSH)

- Internally measured values can be used to check the impact on ongoing production processes (e.g. in the production of plastics, in the food industry, electronics, health products, etc.)

Return on Investment (ROI)

Investment

5.360 €

Savings

115.500 € / year